General Specifications and Further Information

Feedthrough bodies can be specified with a choice of threaded process connections. Feedthroughs with the common tapered threadforms, BSPT (conical gas thread or ‘R’ thread) to BS21, DIN 2999 ISO 7/1 & JIS B0203 and NPT (national pipe tapered thread) to ANSI/ASME B1.20.1 are generally stocked items.

Feedthroughs with parallel threaded process connections, BSPP (parallel gas thread or ‘G’ thread) to BS2779, DIN ISO 228/1 & JIS B0202 UNF/UNEF to ANSI/ASME B1.20.1, PG to DIN 40430, ET to BS31 and ISO metric to DIN13, may also be specified. Feedthroughs with parallel mounting threads need an ‘O’ ring or a gasket seal (not supplied) to prevent leakage at the process connection.

Installation Guidelines:

Stand-Off Length:

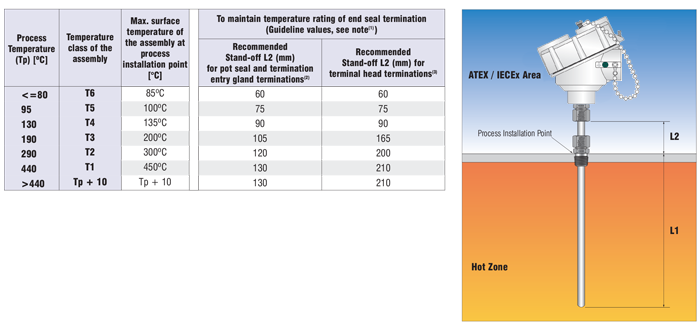

Our sensors are passive units and are not self-heating. However heat transfer along the sheath shall be considered when positioning the sensor in the process to maintain the temperature rating of the end seal termination. See value L2 shown on the typical installation diagram. The below table gives guidance for stand-off length based on the process temperature(1).

T Class:

All the sensors and feedthroughs shown on this catalogue can be used with service temperatures up to 1250ºC dependant on the sheath material used. Typically the hazardous area protection concept is applied to the portion of the assembly outside the process boundary as shown below. When selecting the appropriate sensor design for your application, overall temperature class shall be determined by either:

(a) determined by process temperature as stated in the table below.

Or (b) The temperature class may be determined by temperature measurement on the actual installation. This must be performed when no flammable atmosphere is present. The overall temperature class of the assembly shall be established at the point of exit through the boundary wall into the zoned area.To ensure safe use both calculations (stand-off length to maintain end seal rating and overall t class of assembly) shall be considered.

(2) Values for a standard resin filled pot seal with 90ºC rating. High temperature pot seals can achieve shorter stand-off lengths which shall be calculated by temperature measurement on the actual installation as per method (b) above.

(3) Terminal head terminations have a maximum rating of 60ºC .

If you are in any doubt about whether your application meets the requirements of any of the mentioned standards in this catalogue, TC Ltd recommend that independent advice be taken from the appropriate approving body. The technical data and guideline information presented in this publication is provided in good faith; however, no warranty, express or implied is given whatsoever as to its accuracy, and no liability is accepted for any errors or omissions. The suitability of any products described herein for a particular application is entirely at the discretion of the purchaser as being the best judge for that particular application.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia