Thermocouple Sensors - Thermocouples to your Specifications

What is a thermocouple and how does it work?

Quick summary: A thermocouple is a temperature sensor made by joining two dissimilar metal wires at one end. This junction generates a small voltage when exposed to heat, which is converted into a temperature reading using a known relationship between voltage and temperature.

The two wires are welded together to form a measuring junction (hot junction), which is placed where the temperature needs to be measured. The other ends form a cold junction, often referenced electronically to 0ºC.

As heat is applied to the hot junction, a voltage (EMF) is generated due to the temperature difference between the hot and cold junctions — a principle known as the Seebeck Effect. This voltage is tiny (measured in millivolts) but predictable, and can be translated into temperature using a calibrated thermocouple display or instrument.

For a more detailed explanation, please see our guide: How a Thermocouple Works.

Need help choosing the right thermocouple or RTD sensor?

Speak to one of our experienced UK-based engineers.

Call 01895 252222 or use the Live Chat button.

Custom-built thermocouples for your industry or application

As Europe’s largest manufacturer of thermocouple probes, we supply sensors for industrial, laboratory, and OEM applications — all built to your specification.

We can ship custom built thermocouples typically within five working days.

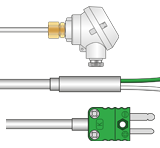

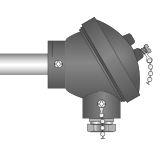

Mineral Insulated Thermocouples

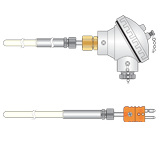

Rugged sensors for most temperature measurement applications. Terminations include connectors, cables, and terminal heads.

Swaged Tip

Rugged sensors for most temperature measurement applications. Terminations include connectors, cables, and terminal heads.

Swaged TipThermocouples

Fast response thermocouples ideal for industrial and other applications.

Fast response thermocouples ideal for industrial and other applications.

Miniature

Thermocouples

Compact thermocouples for precise temperature readings with minimal displacement and fast response.

Compact thermocouples for precise temperature readings with minimal displacement and fast response.

Heavy Duty

Thermocouples

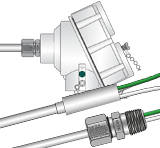

Built for extreme environments, including furnaces, kilns, and boilers. Available with multiple sheath materials.

Built for extreme environments, including furnaces, kilns, and boilers. Available with multiple sheath materials.

High Temperature Thermocouples

Specialized thermocouples for high-temperature conditions, with multiple sheath and termination options.

Specialized thermocouples for high-temperature conditions, with multiple sheath and termination options.

General Purpose

Thermocouples

Wide range of thermocouples to suit many applications, including handheld, surface, bayonet, and patch styles.

Hand Held

Wide range of thermocouples to suit many applications, including handheld, surface, bayonet, and patch styles.

Hand HeldThermocouple Probes

Portable thermocouple probes for general-purpose, surface, and air temperature measurements.

Portable thermocouple probes for general-purpose, surface, and air temperature measurements.

Thermocouples for

Surface Measurements

Thermocouples designed for accurate surface temperature measurement across various applications.

Thermocouples designed for accurate surface temperature measurement across various applications.

AMS2750 Approved

Thermocouples

Calibrated thermocouples meeting AMS2750 standards for heat treatment and vacuum furnace applications.

Calibrated thermocouples meeting AMS2750 standards for heat treatment and vacuum furnace applications.

Industrial Vacuum

Thermocouples

Ceramic sheathed, calibrated thermocouples with low leak rates, designed for vacuum furnace environments.

Ceramic sheathed, calibrated thermocouples with low leak rates, designed for vacuum furnace environments.

ATEX / IECEx Approved

Thermocouples

Thermocouples for use in explosion-proof areas with terminations such as pot seals, terminal heads, and optional 4-20mA transmitters.

Thermocouples for use in explosion-proof areas with terminations such as pot seals, terminal heads, and optional 4-20mA transmitters.

Common Thermocouple Types (IEC 60584-1)

Thermocouples are designated by letter types and conform to IEC 60584-1 standards. Below are the most commonly used thermocouple types in the UK for industrial, laboratory, and OEM applications.

Type K – Nickel-Chromium vs Nickel-Aluminium

Type K thermocouples, also known as Chromel-Alumel, are the most widely used thermocouple type in UK industries. They are reliable, cost-effective, and suitable for general-purpose temperature measurement.

- Temp Range: −200°C to 1,100°C (short-term up to 1,200°C)

- Strengths: Good accuracy, wide range, stable in inert atmospheres

- Limitations: Oxidation drift above 800°C

For detailed specifications, visit the Type K thermocouple page.

Type J Thermocouple – Iron vs Copper-Nickel (Fe/Con)

Type J thermocouples (Iron/Constantan) are one of the few thermocouple types suitable for use in reducing atmospheres.

- Maximum continuous temperature: ~800°C

- Short-term max: up to 1,000°C

- Minimum temperature: -210°C

In oxidising atmospheres above 550°C, Type J degrades rapidly due to oxidation of the iron leg. Below ambient, watch out for condensation, which may cause rust and embrittlement of the iron arm.

This type is typically used in low to medium temperature industrial processes where a reducing environment is present, such as in certain furnaces, ovens, or sealed process chambers.

For more detail, see our dedicated Type J thermocouple page.

Type T Thermocouple – Copper vs Copper-Nickel (Cu/Con)

Type T thermocouples (Copper-Constantan) are commonly used in laboratory and cryogenic applications due to their excellent accuracy and stability at low temperatures.

- Temperature range: -250°C to 400°C

- Excellent repeatability: ±0.1°C in the -200°C to 200°C range

Above 400°C, the copper leg oxidises rapidly, making Type T unsuitable for higher temperature use. It also has a relatively high thermal conductivity, which may affect some measurements.

Note: The negative leg uses a specific copper-nickel alloy different from that in Type J thermocouples, so these types are not interchangeable.

For more detail, visit our dedicated Type T thermocouple page.

Type N Thermocouple – Nicrosil-Nisil

Type N thermocouples were developed as a more stable and oxidation-resistant alternative to Type K, particularly for high-temperature industrial applications.

- Composition: Nicrosil (positive leg) and Nisil (negative leg)

- Improved stability: Excellent resistance to oxidation-related drift at high temperatures

- Temperature range: Up to 1,280°C continuous use, higher for short periods

Type N thermocouples are especially suitable where long-term reliability and repeatability are critical, outperforming not only Type K but also other base metal thermocouples in many harsh environments.

For further technical details, visit our dedicated Type N thermocouple page.

Type R Thermocouple – Platinum-13% Rhodium vs Platinum

Type R thermocouples are closely related to Type S but offer slightly higher thermoelectric output and improved long-term stability.

- Composition: Platinum (87%) vs Platinum-13% Rhodium

- Performance: Higher output than Type S with similar temperature range and stability

- Applications: Common in high-accuracy lab and industrial settings, preferred over Type S in many cases

Type R is often the preferred choice where precision and consistency are essential in high-temperature environments.

Learn more on our dedicated Type R thermocouple page.

Other thermocouple types you may encounter include Type S, Type E, Type B, and Type C, which are typically used in specialised or high-temperature environments.

Explore our in-depth Thermocouple & RTD Guide — a technical resource developed for engineers and specifiers. Covers sensor selection, installation practices, standards and tolerances, colour codes, wiring configurations, sensor theory and more.

What is the most accurate type of thermocouple?

Type T thermocouples are the most accurate among the base metal types, with a Class 1 material tolerance of ±0.5°C, as defined in IEC 60584-1.

Note that this accuracy applies over a limited temperature range. For a full breakdown of tolerances across all thermocouple types, see our thermocouple tolerances page.

Do I need a thermocouple or an RTD?

The choice between a thermocouple and an RTD (Pt100) depends on your application's temperature range, accuracy needs, and environmental conditions.

- Thermocouples: Wide temperature range, fast response time, compact, durable, and low cost. However, they are less accurate and stable than RTDs and can drift over time. They require thermocouple-specific cable and connectors.

- RTDs (Pt100): High accuracy and stability, excellent repeatability. However, they are more fragile, less resistant to vibration, and respond more slowly to temperature changes.

What are the different types of thermocouple junction?

Insulated Thermocouple Junction Diagram

An insulated thermocouple junction features the hot junction separated from the sheath, providing a floating output. This design delivers very high insulation resistance — mineral insulated thermocouples typically exceed 100 megohms — improving electrical safety and ensuring stable, accurate temperature readings.

Grounded Thermocouple Junction Diagram

A grounded thermocouple junction is welded directly to the sheath tip, creating an earthed output. This setup offers faster response times to temperature changes, enhancing measurement speed and accuracy — especially valuable in dynamic or industrial environments.

Exposed Thermocouple Junction Diagram

In an exposed thermocouple junction, the hot junction is directly exposed to the environment, delivering the fastest response time. This makes it ideal for accurate air temperature measurement in ducts and airflow applications. Note that mineral insulated exposed junctions are limited to a maximum operating temperature of 600°C, restricting use in higher-temperature settings.

All of these configurations are types of the hot junction. They should not be confused with the cold junction, which serves as the reference point for temperature measurement. Cold junction compensation is typically integrated into instrumentation to ensure accurate and reliable temperature readings.

Further Information on Thermocouples

- Complete Guide to Thermocouple and Resistance Thermometry – First published in 1993, this guide has been requested by over 500,000 engineers, buyers, and specifiers. Recognised across the industry as a definitive reference, the guide is now available as a fully revised and expanded online resource.

- How a Thermocouple Works – Understand the principles behind thermocouple temperature measurement, including hot junctions, cold junction and voltage generation.

- Thermocouple Colour Codes – A reference guide for identifying thermocouple types based on wire insulation and standardised colour coding.

- Types of Thermocouples – Explore the different thermocouple types, their materials, temperature ranges, and best applications.

- Thermocouple Tolerances – Learn about accuracy levels and measurement tolerances across various thermocouple standards.

- Temperature Probes – Discover a wide range of thermocouples and sensors for precise temperature measurement in diverse applications.

- Thermocouple vs. RTD Pt100 – Compare thermocouples and RTDs to determine the best sensor for your temperature measurement needs.

- Insulation Materials for Thermocouple Cables – Learn about insulation options for thermocouple cables and how they impact durability and electrical performance.

Frequently Asked Questions

- How do I order a custom thermocouple?

All our thermocouples are custom-made in our factory to meet your specific needs. You can choose the thermocouple type, sheath diameter, cable length, junction, and termination. Ideally, please use the enquiry form on any product page or contact us for a quote. We also stock a wide range of thermocouples, Pt100's cables, and connectors for fast dispatch via our online store. - How do I choose the right thermocouple for my application?

The right thermocouple depends on temperature range, accuracy, environment (moisture, vibration, corrosion), and how it's mounted. We supply sensors for everything from industrial ovens to R&D labs. Talk to our engineers for expert guidance on specifying the best solution. - What is a thermocouple and how does it work?

A thermocouple is a type of temperature sensor made by joining two dissimilar metals. When exposed to a temperature difference, it produces a voltage that correlates to temperature. Thermocouples are widely used in industrial, scientific, and process applications due to their wide temperature range and durability. - How do I choose the right thermocouple for my application?

Choosing the right thermocouple depends on your temperature range, accuracy needs, mounting type, and environmental conditions (e.g., moisture, vibration, chemicals). We supply thermocouples across many industries and environments — if you're unsure, please speak to one of our engineers for expert guidance. - What is the maximum temperature rating of your thermocouples?

Our high-temperature thermocouples can measure up to 1400°C using mineral insulated cable, and up to 1600°C with ceramic sheaths. These are suitable for industrial furnaces, kilns, and heat-treatment applications. Check product specs or contact us for guidance on your specific environment. - What thermocouple types are best for high-temperature industrial applications?

Type K and Type N thermocouples are commonly used in high-temperature industrial processes due to their wide range and durability. For extreme environments or continuous operation above 1200°C, platinum-based thermocouples like Type S or Type R are preferred. We supply all of these in various sheath materials to suit your plant conditions. - Can I use thermocouples outdoors or in harsh environments?

Yes, but the choice of sheath material and construction is critical. Stainless steel sheaths provide good general resistance, while Inconel and ceramic sheaths handle corrosive or high-temperature environments better. We offer IP-rated and custom thermocouples for harsh or outdoor installations. - What’s the difference between thermocouples and RTDs?

Thermocouples offer a wider temperature range and faster response, ideal for dynamic or high-heat environments. RTDs (like Pt100s) provide better accuracy and stability over time, but have a narrower range and are less robust. We supply both and can help you choose based on your process needs. - Do I need special cables or connectors for thermocouples?

Yes. Thermocouples require matching thermocouple extension cable and connectors made from the same alloys to maintain measurement accuracy. We stock thermocouple cables, plugs, and panels for all standard types (K, J, T, N, etc.). - Can you supply custom thermocouples for my application?

Absolutely. We specialise in custom thermocouple designs — including specific sheath lengths, diameters, mounting styles, and connector types. Contact us with your requirements and we’ll build to your specification, typically with fast turnaround. - Do your thermocouples comply with IEC 60584 standards?

Yes — all our thermocouples are manufactured using IEC 60584-compliant materials, including Class 1 and Class 2 tolerances. Calibration certificates are available on request, and we also offer UKAS-certified calibration services if required.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia