Thermocouple Cold Junction Compensation

Cold Junction techniques for Thermocouple Thermometry

What is Cold Junction Compensation?

Thermocouples use the Seebeck effect to generate a voltage proprtional to temperature changes. There are calibration tables (emf tables) for each thermocouple type, relating output voltage to the temperature of the measuring junction. Throughout thermocouple thermometry it is necessary to refer sensor voltage output to these in some way to ascertain true temperature.

Most importantly, different net voltage outputs are produced for a given temperature difference between the measuring and reference junctions if the reference junction temperature itself is allowed to vary. So, the calibration tables mentioned above always expressly assume that the reference junction is held at 0°C.

Simple Copper Junctions in Ice

This can be achieved by inserting the copper junction(s) into a melting ice bath, via insulating glass tubes, or into a temperature controlled chamber, like an isothermal block with suitable temperature sensors. For industrial measurement today, this kind of function is normally performed by temperature correcting electronics - while linearising electronics (usually digital), harnessing curve fitting techniques, look after the inherent non-linearities as per the calibration tables.

Practical Industrial Compensation

Essentially, reference temperature variations are sensed by a device such as a thermistor as close as possible to the reference junction. An EMF is then induced which varies with temperature so as to compensate for temperature movements at the reference terminals.

Need advice on Cold Junction Compensation or any other aspect of temperature measurement?

Contact one of our experienced engineers on

01895 252222 or use the Live Chat button.

Popular Thermocouples

Mineral Insulated Thermocouples Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

General Purpose Thermocouples

Rugged sensors, ideal for most applications. Vast choice of terminations e.g. pot seals, cables, connectors, heads etc.

General Purpose Thermocouples

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

A wide range of thermocouples to suit many applications. Hand held, surface, bayonet, bolt, patch styles etc.

Cold Junction Compensation Methods

As explained earlier, thermocouples provide an output which is related to the temperatures of the two junctions. For them to function as absolute temperature measuring devices, rather than differential, the reference junctions must be maintained at a known temperature (see diagram 5.1).

Compensation in Laboratory Use

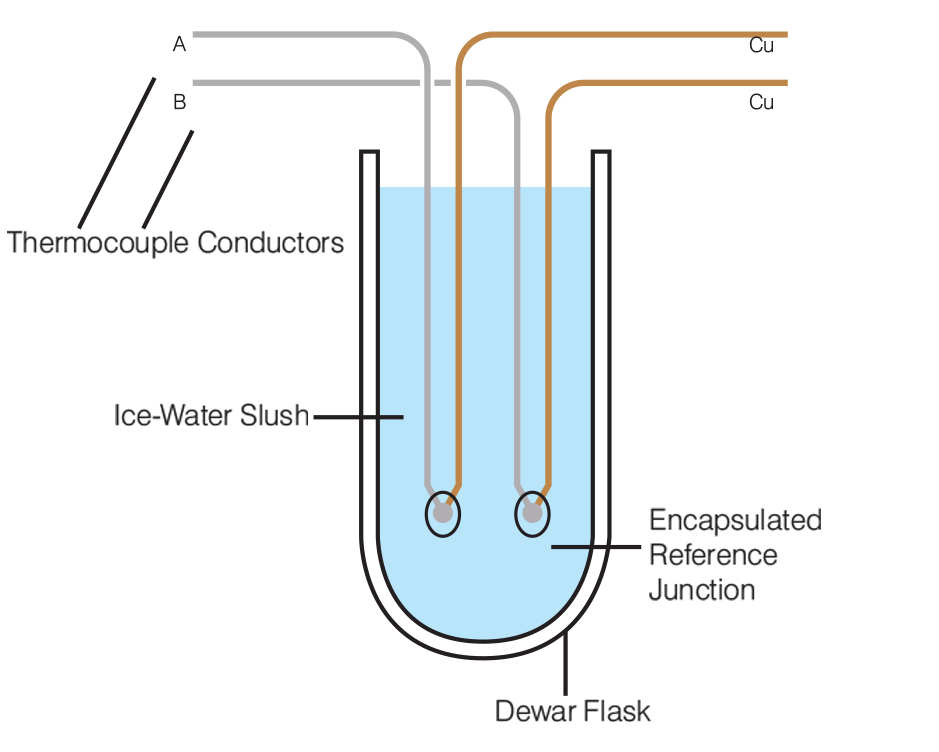

An established, simple method of maintaining reference temperature stability, still used in laboratories today, is to immerse the reference junctions in a slush of melting ice. Given that you have pure water ice, the temperature plateau during the melting process is established at a constant 0°C within ±0.001°C. In practice, all that is required is an ice-filled Dewar flask and the set-up is then potentially quite accurate. However, it does require regular attention and replenishment for anything other than short term use and is clearly inappropriate for industrial requirements. Sources of error include the 4°C reference offset which will occur if enough ice melts so that the reference junctions are actually immersed only in water - with the ice floating above! Also if the ice used has been stored in a freezer, it will be a lot colder than 0°C.

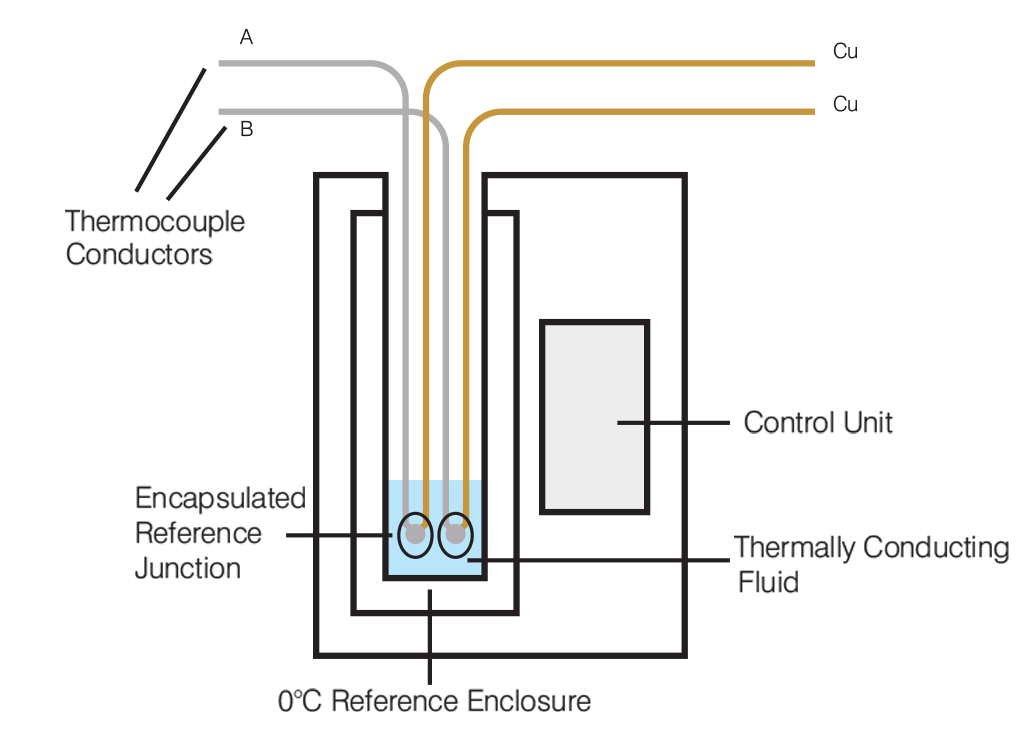

Not surprisingly, there are more practical cold junction alternatives for industrial use, also designed to provide a reference temperature of 0°C. One involves an automatic temperature-controlled enclosure, into which the reference junctions are inserted. This holds the junctions continuously at the ice point, using semiconductor thermoelectric cooling (Peltier) devices. Here temperature errors are typically less than 0.1°C. The use of an ice point reference, or its equivalent (however generated), is still preferable to the alternatives, not only on the grounds of accuracy and stability, but also because the reference tables for thermocouples are based on a 0°C reference temperature.

Integral Electronic Cold Junction (CJC) for Temperature Measurement

Another very common device today is based on a temperature sensitive electrical network (there are several options including wheatstone bridge networks) which tracks the reference junction temperature and develops an equivalent voltage. Such so-called cold junction compensation is incorporated into each thermocouple circuit, or the measuring instrument or transmitter itself at the point of connection (see below). These devices are available as discrete modules, mains or battery powered and provide for accuracy within a few °C.

Many of the instruments designed to operate with thermocouples provide a terminal block for direct connection to the thermocouple or extension wire conductors without any need for a separate reference junction as such. Such devices as electronic thermometers, temperature controllers, data loggers, etc, frequently incorporate their own equivalent ice point reference voltage generators (as described above).

The temperature at the connection point might be determined by an integral rtd , thermistor or transistor, and thus a suitable reference voltage developed. Incidentally, it is worth taking care over the physical siting of the reference generator, since accuracy and stability of the thermocouple reading are dependent on the network involved actually being in the same temperature environment as the connections themselves.

In any event, the reference voltage can be added to the thermocouple output either by inclusion in the electrical circuit, or, particularly in the case of controllers, data loggers and other digital systems, by data manipulation in the temperature calculations. In fact, many modern controllers, loggers, etc can accommodate the latter approach for all cold junction compensation needs.

Multi-thermocouple Systems

For large schemes involving many thermocouples, racking systems and cabinets are also available having, say, 100 equivalent reference (cold) junctions already fitted into a uniform temperature enclosure. The enclosure might be an ice point unit as already described, or it might equally be a thermally stable metal block which maintains a reasonably steady temperature close to that of its surroundings. In the latter case, the temperature of the block is continuously monitored by an electrical compensator, and again, the equivalent ice point voltage is then available to be added to each thermocouple signal output - electrically, or numerically.

Elevated Temperatures

Beyond these, there are also reference units designed for enclosures operating at elevated temperatures. These can be useful in areas with particularly high ambient temperatures, but the thermocouple outputs will have to be adjusted to the equivalent 0°C values. In essence, as long as the reference temperature is known, the temperature of the measuring junction can be derived by adding in a correction factor from standard tables covering the thermocouple concerned.

Figures 5.1: Dewar flask with Reference Junctions

Figures 5.2: Temperature controlled enclosure

What happens if you don't perform cold junction compensation in a thermocouple circuit?

If cold junction compensation is omitted, then the result will be be inaccurate termperature readings for the following reasons:

- Reference Junction Variation

For internal CJC, the reference junction is assumed to be at a known temperature (often room temperature which is referenced to 0ºC). If this reference junction temperature deviates from the assumed value, the thermocouple circuit will produce an offset in the voltage output, leading to incorrect temperature readings. - Uncompensated Voltage

The thermocouple generates a voltage proportional to the temperature difference between the measurement and reference junctions. Without CJC, the voltage measured by the instrument won't accurately represent the temperature at the measurement junction. This discrepancy can lead to readings significantly different from the actual temperature.

What is the effect applications of not using CJC?

Process Control

In industrial applications, incorrect temperature readings can lead to improper process control. For instance, in manufacturing, inaccurate temperature measurements can impact the quality of products or the efficiency of the production process.

Safety Concerns Where temperature monitoring is critical for safety (e.g., in chemical plants or laboratories), relying on inaccurate readings due to lack of CJC can lead to unsafe operating conditions or processes.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia