IECEx Approved Thermocouple Feedthrough Assemblies for the Petrochemical, Oil and Gas Industries

Request a Quote

Data Sheet

Request a Quote

Data Sheet

TC - Trusted by UK manufacturers, OEMs, and research labs for over 50 years.

Also available with ATEX Approval

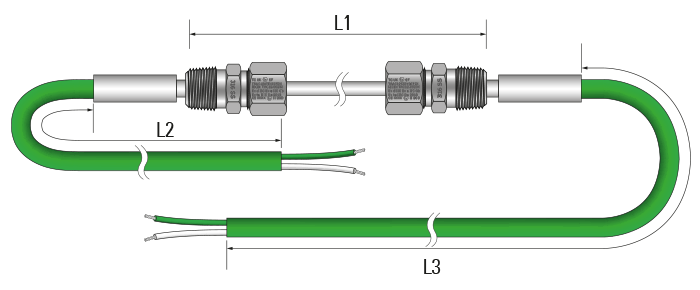

To extend thermocouple signals over medium to long distances (120 metres maximum), our mineral insulated IECEx approved thermocouple feedthrough assemblies are recommended. This product is useable in even the most arduous conditions.

- A wide range of protection concepts are available for use in Zones 0, 1 & 2. See table below for details

- The following thermocouple types are available: K, T, J, N, E, R, S and B

- Suited to arduous operating conditions due to the high integrity construction

- Available in sheath diameters 1.0mm, 1.5mm, 2.0mm, 3.0mm, 4.5mm & 6.0mm in a wide variety of sheath materials

- A floating output with high insulation resistance is given via an insulated measuring junction

- Typically supplied with either PVC, PFA or fibreglass insulated extension cables. Other cables available.

- These sensors can be UKAS calibrated

Available with the following approvals:

| Protection Type | Description | Zone |

| Ex nA IIC Gc | Non-Sparking (Gas) | 2 |

| Ex d IIC Gb | Flameproof (Gas) | 1 |

| Ex ia IIC Ga / IIIC Da | Intrinsically Safe (Gas/Dust) | 0/20 |

| Ex tb IIIC Db | Enclosure (Dust) | 21 |

| Ex tc IIIC Dc | Enclosure (Dust) | 22 |

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia