Reference (Cold) Junction Compensation Methods

Contents

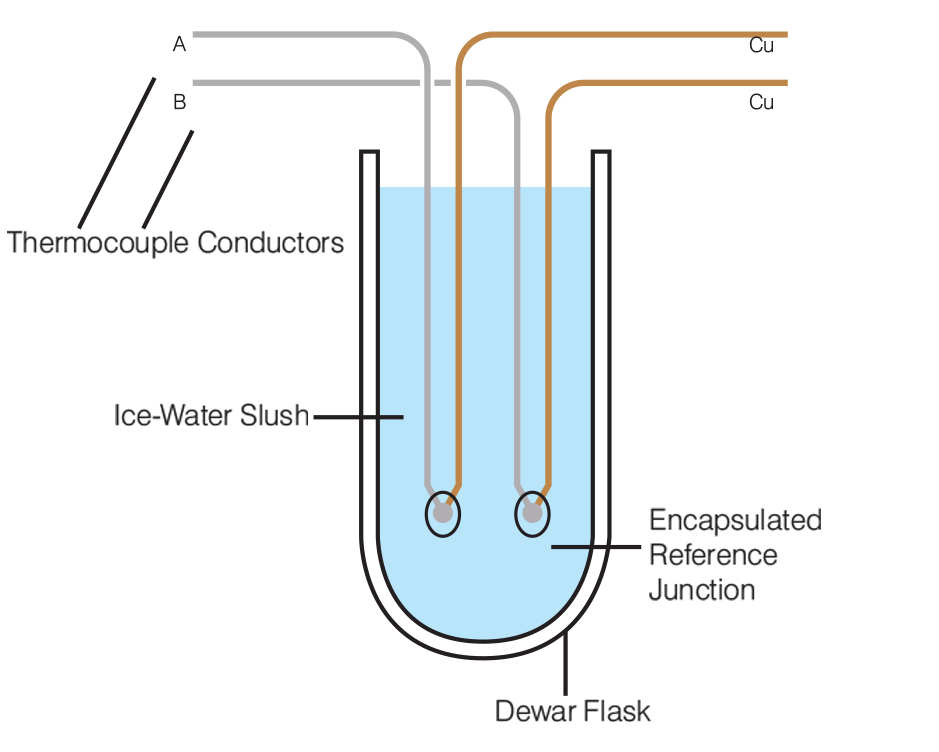

Thermocouples measure the temperature difference between two junctions - the measuring (hot) junction and the reference (cold) junction. To obtain an accurate absolute temperature reading, the reference junction must be held at a known, stable temperature (see Figure 5.1).

Ice Bath Reference (Laboratory Method)

A traditional but precise method, still used in laboratory environments, is to immerse the reference junctions in a melting ice bath. When using pure ice and distilled water, the temperature remains stable at 0°C ±0.001°C during the phase change.

A basic setup involves an ice-filled Dewar flask, which is simple yet accurate.

However, this method has clear drawbacks:

- It requires frequent maintenance and replenishment, making it impractical for industrial use.

- If the ice melts and the junctions sit in water without touching ice, the temperature may drift toward 4°C, introducing errors.

- Ice taken directly from a freezer may be colder than 0°C and require time to stabilize.

Figure 5.1: Dewar Flask with Reference Junctions

Industrial Reference Junction Alternatives

To overcome the limitations of ice baths, modern cold junction compensation methods are widely used in industrial settings. These ensure thermocouples remain accurate without manual intervention.

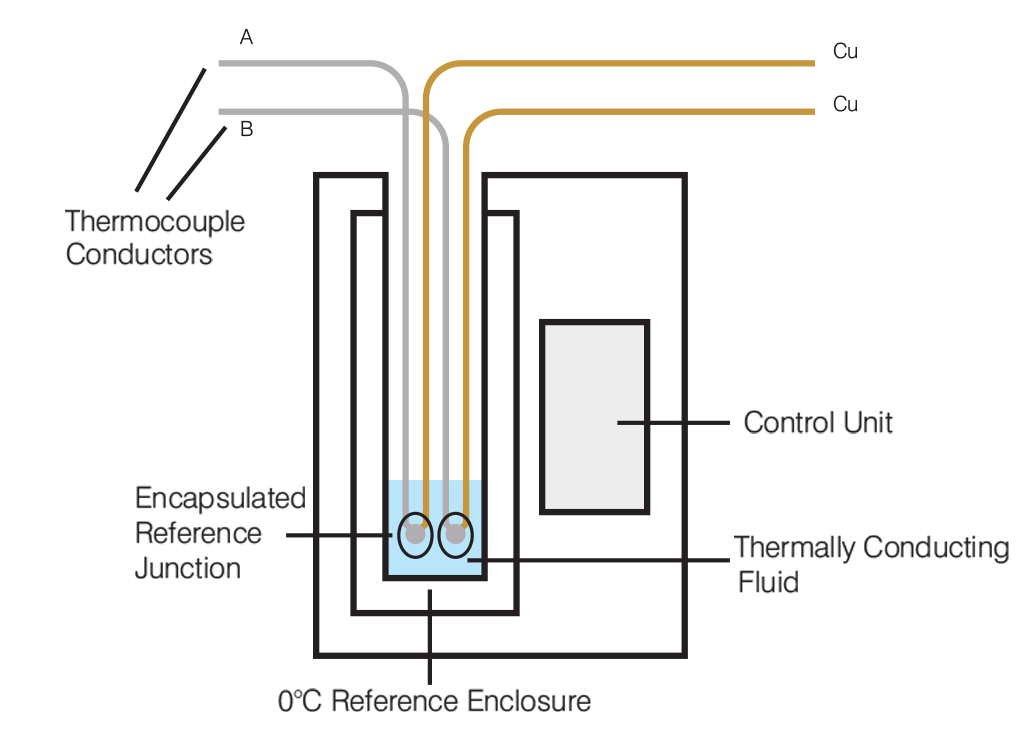

A. Temperature-Controlled Enclosures

These enclosures maintain the reference junction at 0°C using thermoelectric (Peltier) cooling. Junctions are inserted into the device, and the temperature is actively stabilized.

- Offers ±0.1°C accuracy

- Delivers a true ice point equivalent

- Ideal for applications where precision is critical

Figure 5.2: Temperature-Controlled Enclosure

B. Electronic Cold Junction Compensation

Most modern instruments (e.g. temperature controllers, data loggers, digital thermometers) include built-in cold junction compensation. Here's how it works:

- A temperature sensor (e.g. RTD, thermistor, or transistor) monitors the terminal block temperature.

- The instrument generates a voltage correction equivalent to the difference from 0°C.

- Added electronically to the thermocouple signal, or

- Applied digitally during signal processing.

This correction is either:

These systems typically offer accuracy within a few °C, making them suitable for most general-purpose applications.

Multi-Channel and Rack-Based Systems

For large installations involving many thermocouples, manufacturers offer rack-mounted reference junction systems, often built into:

- Temperature-controlled enclosures (ice point or otherwise)

- Thermally stable metal blocks (held at ambient or known temperature)

- A consistent thermal environment

- A monitored reference temperature

- Either analog or digital compensation for each thermocouple signal

Each channel in the system provides:

These systems ensure consistency and accuracy across high-density thermocouple networks.

High-Temperature Reference Units

In environments where ambient temperatures are elevated (e.g. industrial furnaces or engine bays), special reference junction enclosures can operate at higher fixed temperatures. Compensation is still applied by:

- Monitoring the enclosure temperature

- Applying an appropriate correction to convert readings back to a 0°C reference baseline

As long as the reference temperature is accurately known, the thermocouple measurement can be corrected using standard thermocouple tables.

Summary: Choosing the Right Cold Junction Method

| Method | Accuracy | Best for | Notes |

|---|---|---|---|

| Ice Bath (Dewar Flask) | ±0.001°C | Laboratories | High accuracy, but impractical for industry |

| Peltier Cooled Enclosure | ±0.1°C | Industrial precision applications | Reliable and stable |

| Built-in Electronic Compensation | ±1–2°C | General-purpose instruments | Widely used, low maintenance |

| Multi-Channel Systems | ±0.1–2°C | High-density industrial systems | Ideal for control cabinets |

| High-Temp Reference Units | Varies | Harsh environments | Requires compensation to 0°C |

Note: The information in this guide is provided for general informational and educational purposes only. While we aim for accuracy, all data, examples, and recommendations are provided “as is” without warranty of any kind. Standards, specifications, and best practices may change over time, so always confirm current requirements before use.

Need help or have a question? We’re here to assist — feel free to contact us.

Further Reading

What are the various thermocouple types?

Explore the features and characteristics of the various thermocouple types

Thermocouple Output Tables

View EMF versus Temperature tables for all thermocouple types.

What are the thermocouple colour codes?

Explore thermocouple colour codes for cable and connectors.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia