Siting Thermocouples and RTDs

Contents

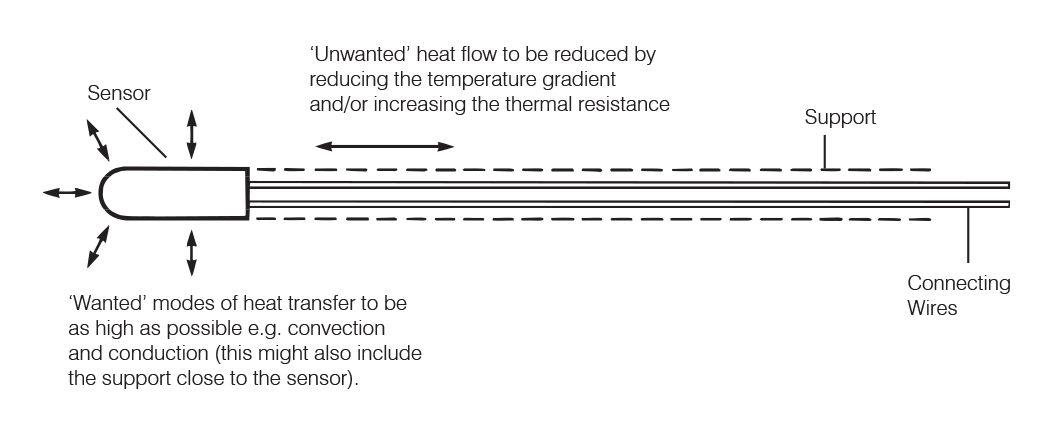

Accurate temperature sensing depends on placing the sensor in a way that ensures it reaches the same temperature as the medium being measured. In other words, good thermal contact and minimal heat loss along the protection tube, supports, or internal wiring are essential (see Figure 4.1).

Figure 4.1: Sensor Heat Transfer Modes

Key Principles for Accurate Sensor Placement

To achieve reliable temperature measurements, follow these three essential principles:

- Ensure Good Thermal Linkage

-

For fluids:

- Place the sensor in the region of highest flow velocity.

- Prefer cross-flow orientation for better responsiveness.

- In slow-moving fluids, consider external fins to improve heat transfer.

-

For solids:

- Insert sensors into tight-fitting holes.

- Use thermal compounds such as cements, fillers, heat-transfer grease, or high-conductivity liquids.

-

For surfaces:

- Use thermal pads, conductive pastes, or soldered attachments for better thermal contact.

- Minimize Heat Conduction Errors

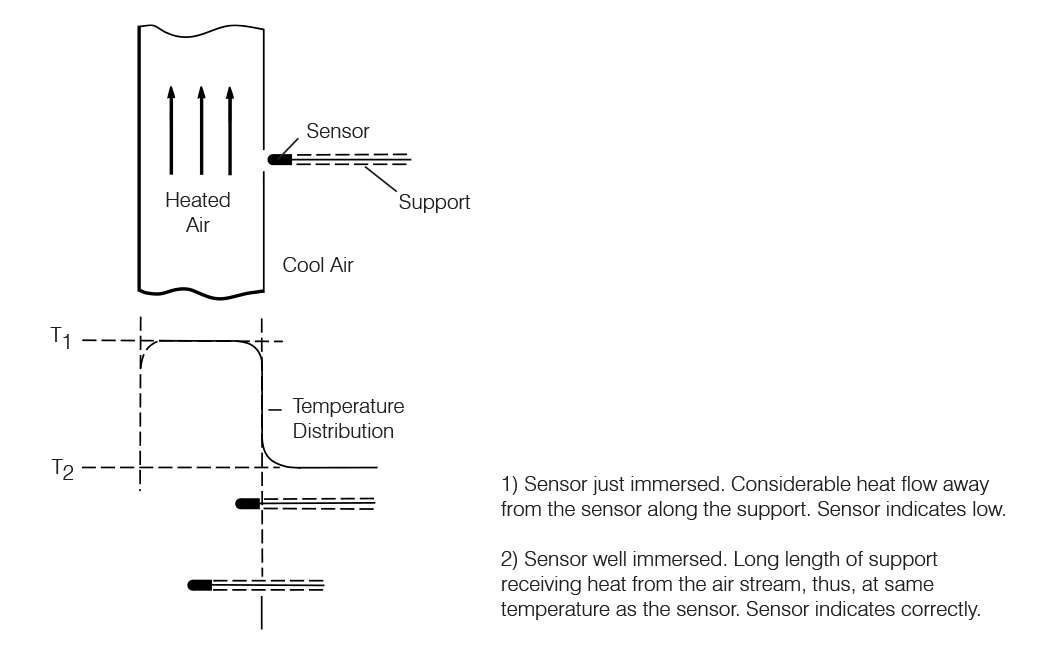

- Maximizing sensor immersion depth (see Figure 4.2).

- Using thin-walled stainless steel pockets or supports with high axial thermal resistance.

- Selecting small-diameter, low thermal conductivity lead wires.

- Running wires along the surface for some distance before routing away to reduce conduction.

Prevent heat flow along supports and wires by:

- Minimize Sensor-Induced Temperature Disturbance

In some cases, the sensor itself can disrupt the medium’s natural temperature distribution

- Keep the sensor size small relative to the measurement area.

- Match the sensor shape to the surface geometry.

- Use insulation or shielding to isolate the sensor from external influence.

Example:

-

For surface measurements on a pipe, if the pipe is:

- Thin-walled and conductive

- Carries fluid with sufficient temperature differential and stable flow ...then a surface-mounted sensor with insulation can give accurate readings.

⚠️ Note: RTDs may suffer from strain due to thermal expansion mismatches between the sensor and the mounting surface. This can lead to resistance changes and measurement error.

Figure 4.2: Importance of Sensor Immersion Depth

Heat Transfer Mechanisms

Understanding how heat moves helps in designing better installations. The three core heat transfer modes are:

Conduction

Conduction is heat transfer through molecular motion within a material.

- Metals like silver and copper conduct heat very well.

- Air and other gases are poor conductors.

- Sensor elements and their protective sheaths mostly rely on conduction.

Convection

Convection occurs when heat transfers between a body and a moving fluid (liquid or gas).

- Forced convection uses pumps, fans, or stirrers.

- Natural convection relies on buoyancy from temperature-induced density changes.

Most temperature sensors in fluids rely on convection at their outer surface to pick up the medium’s temperature.

Radiation

All bodies above absolute zero emit thermal radiation.

- Radiated energy increases with temperature to the fourth power.

- The effect becomes critical at high temperatures, such as in furnaces.

Radiation depends on:

- Surface temperature and emissivity

- Distance and angle between surfaces

- Obstructions and shielding

Unwanted radiation effects:

In low-velocity hot gas streams, sensors may lose heat to surroundings, underreading the actual gas temperature. Conversely, in cooler streams surrounded by hotter walls, sensors may overread.

Solutions:

- Use low-emissivity sensor housings

- Add radiation shields to isolate the sensor from its surroundings

Stagnation Temperature in High-Velocity Gas Streams

In fast-moving gases, the sensor can pick up dynamic heating due to the velocity of the gas flow.

There are two temperature types:

- Static Temperature (Ts): the actual gas temperature

- Total (Stagnation) Temperature (Tt): includes heating from gas velocity

Special stagnation probes can be used to measure Tt, from which Ts is calculated using:

Ts = Tt / (0.5 × (γ − 1) × M² + 1) where:

- γ = ratio of specific heats (Cp/Cv)

- M = Mach number of the gas

Example Heating Effects in Air (Atmospheric Pressure):

| Velocity (m/s) | Temperature Rise (°C) |

|---|---|

| 45 | 1 |

| 145 | 10 |

| 245 | 30 |

Summary

Accurate temperature measurement depends on good thermal contact and proper installation. Sensors should be placed in fast-flowing fluid regions or embedded in solid materials using conductive compounds. It's important to minimize heat loss along supports and wires by using low-conductivity leads and ensuring sufficient immersion depth. Sensor presence can also disturb the temperature being measured, especially on surfaces, so small, well-fitted, and insulated sensors are best.

Heat transfer to the sensor occurs via conduction, convection, and radiation. Each mode affects accuracy differently depending on installation conditions. In fast-moving gas flows, stagnation temperature effects may raise the measured temperature.

Note: The information in this guide is provided for general informational and educational purposes only. While we aim for accuracy, all data, examples, and recommendations are provided “as is” without warranty of any kind. Standards, specifications, and best practices may change over time, so always confirm current requirements before use.

Need help or have a question? We’re here to assist — feel free to contact us.

Further Reading

RTD vs Thermocouple – Choosing the Right Sensor

Explore the features and characteristics of thermocouples and RTDs

RTD Output Tables

View Resistance versus Temperature tables for all Pt100 sensors.

What are the RTD colour codes?

Explore RTD colour codes and wiring configurations.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia