Thermocouple Styles

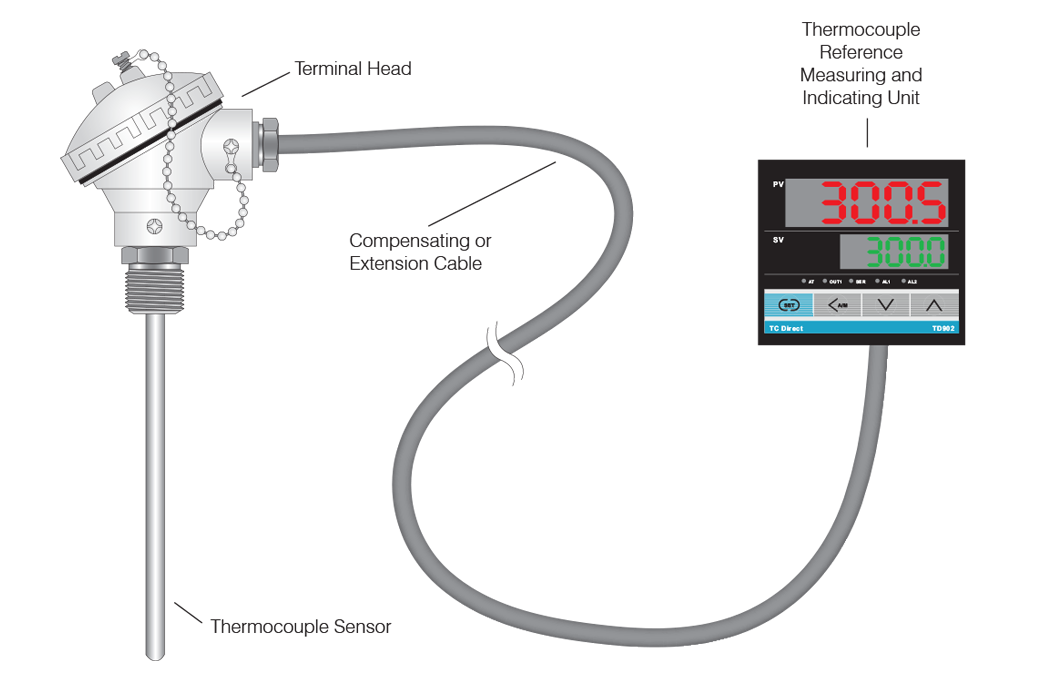

Figure 1.1: A Typical Industrial Thermocouple

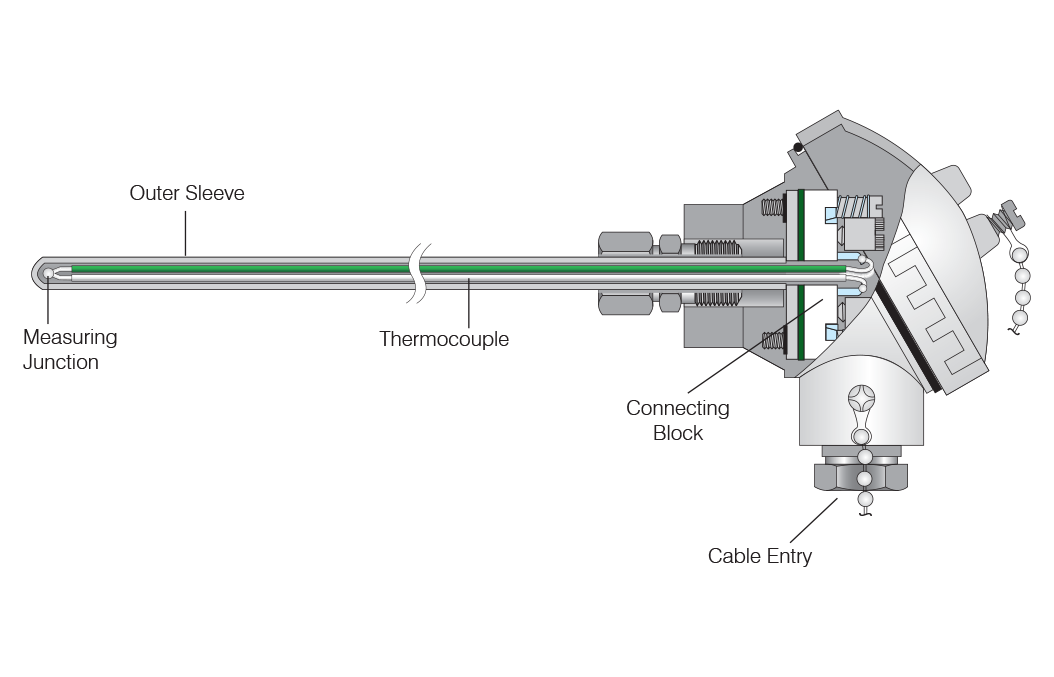

Basic forms include bare wire thermocouples with insulation suited to the environment, encased in metal or ceramic sheaths for protection. These may come as standalone sensors or as part of probes housed in protective tubes or thermowells (Figure 1.2).

Figure 1.2: Enclosed Thermocouple Probe and Head

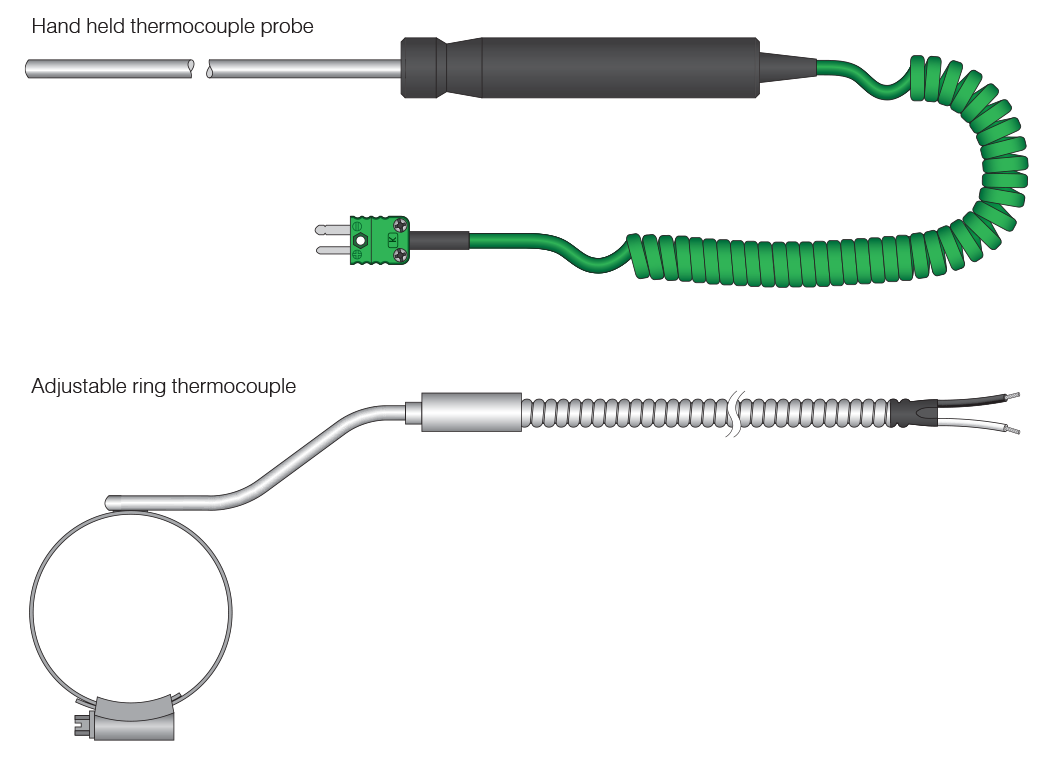

Sizes range from ultra-thin (~0.25mm) to heavy-duty designs (up to 20mm or more). Styles vary widely - welded sheath probes, bolt-style probes, hand-held and surface probes, pipe-clip probes, and many more (Figure 1.3). Probes are often specified by sheath and insulation materials, junction grounding, and connector types.

Figure 1.3: Hand-held Probe and Pipe Probe

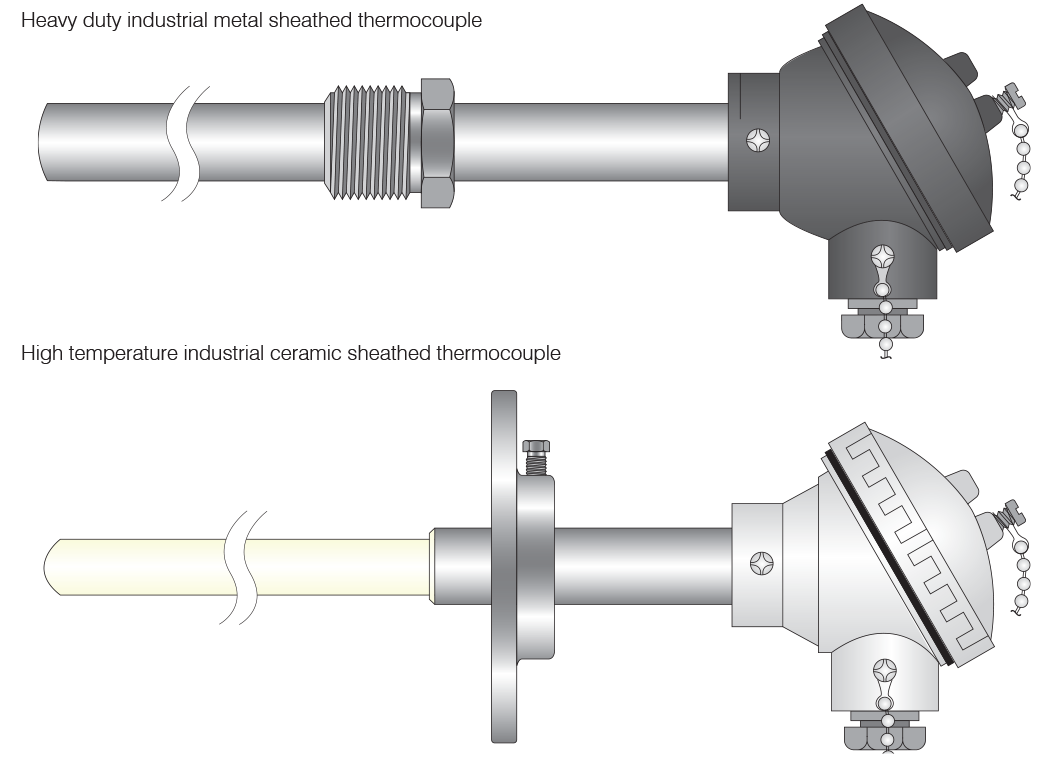

There are specialised versions for high-temperature or heavy-duty environments (Figure 1.4), including sensors with head-mounted terminals and thermowell assemblies. In some cases, flexible stainless steel sheaths and pressure seals are used, such as in autoclave or plastic processing applications.

Figure 1.4: Heavy Duty Industrial Metal Sheathed and High Temperature Ceramic Sheathed Thermocouples with Terminal Head Assemblies

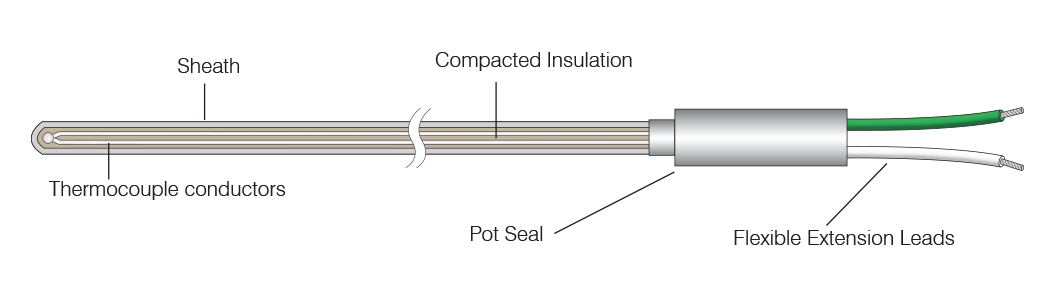

Many industrial sensors are made using mineral insulated (MI) cable, which embeds thermocouple wires in compressed mineral powder within a metal sheath (Figure 1.5). This construction offers durability, hermetic sealing, and wide customizability in terms of length and diameter—from 0.25mm to over 10mm and up to tens of metres long. For fast response applications, the MI thermocouple junction can be exposed.

Figure 1.5: Typical Mineral Insulated Thermocouple Sensor Construction

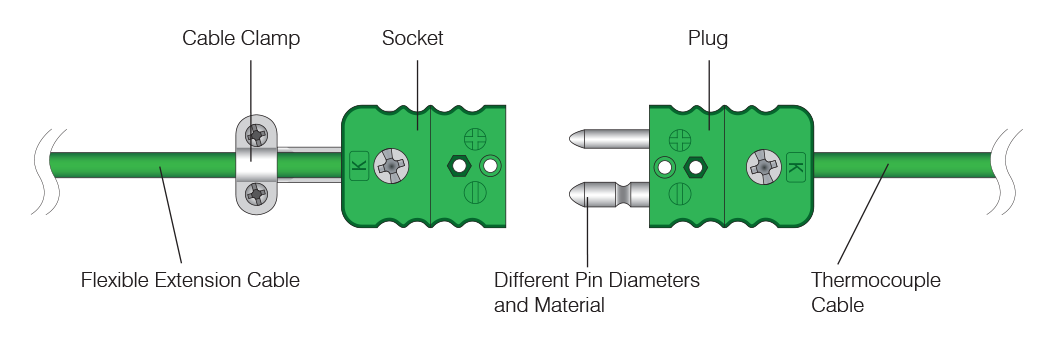

Connection options include terminal boxes or miniature or standard plugs/sockets with thermoelectric pins that match the thermocouple material (Figure 1.6). These ensure accurate signal integrity and are discussed in more detail later in this guide.

Figure 1.6: Typical Thermocouple Connectors

Summary

Thermocouples can be constructed simply in the lab using bare wire, welding techniques, and basic insulation, offering an effective and highly flexible approach for experimentation and measurement. In industrial settings, however, thermocouples are supplied in a vast range of forms to suit specific application demands - from compact, handheld sensors to heavy-duty, mineral-insulated probes capable of withstanding extreme environments. These sensors vary not only in size and material, but also in configuration, grounding method, and connection type. Whether made manually or purchased commercially, the core function remains the same: to provide a reliable and responsive means of measuring temperature across a broad range of conditions.

Note: The information in this guide is provided for general informational and educational purposes only. While we aim for accuracy, all data, examples, and recommendations are provided “as is” without warranty of any kind. Standards, specifications, and best practices may change over time, so always confirm current requirements before use.

Need help or have a question? We’re here to assist — feel free to contact us.

Further Reading

What are the various thermocouple types?

Explore the features and characteristics of the various thermocouple types

Thermocouple Output Tables

View EMF versus Temperature tables for all thermocouple types.

What are the thermocouple colour codes?

Explore thermocouple colour codes for cable and connectors.

France

France Germany

Germany Spain

Spain Netherlands

Netherlands Italy

Italy Hungary

Hungary United States

United States Australia

Australia